Designed for Small & Sensitive Surfaces

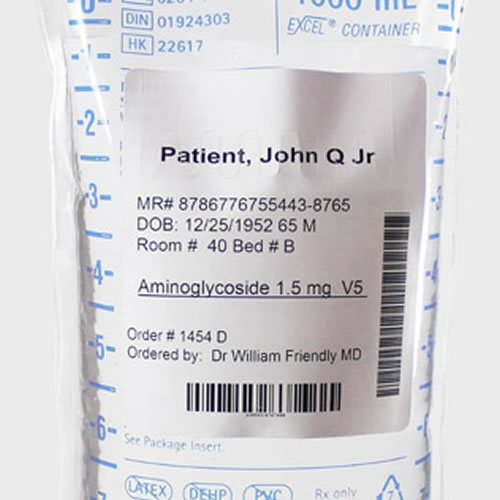

Syringes present unique labeling challenges due to their small size, narrow surface, and the critical nature of the information displayed. Our custom syringe labels are engineered to adhere securely to curved, often smooth or sterilized surfaces without compromising clarity or function. Whether used for hospital procedures, vaccinations, or lab testing, our labels ensure accurate identification from filling to administration.

Label Features & Performance

We provide labels tailored to syringe use cases, with key features including:

Reliable adhesion to curved plastic or glass barrels

High legibility for small-font content (dose, lot number, expiration)

Smudge- and moisture-resistant materials

Option for wrap-around or flag-style formats

Compatibility with sterilization processes (EO, gamma, steam, etc.)

Custom die-cut sizes to match different syringe capacities (0.5 ml to 60 ml+)

These labels are commonly applied manually or via automated labelers in cleanroom or controlled environments.

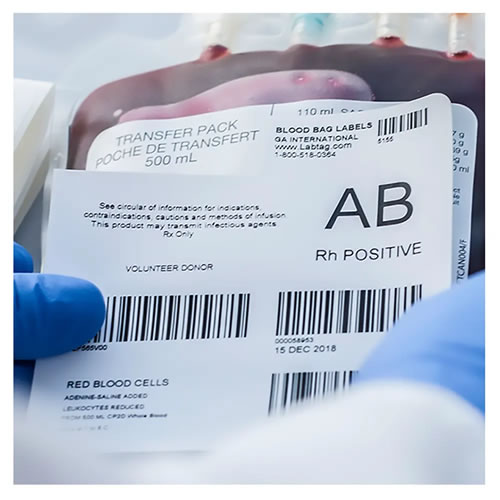

Common Applications

Our syringe labels are used across:

Hospitals and clinics for prefilled syringes and unit dosing

Pharmaceutical production for vaccine and medication syringes

Laboratories for specimen and sample tracking

Medical device packaging where small, curved label surfaces are required

Veterinary clinics for dosage labeling on syringes

We also support multi-language or variable content printing for export or multi-region use.

Materials & Printing Options

To meet strict healthcare and pharmaceutical standards, we offer:

Materials:

White PP film: Waterproof and chemical-resistant, ideal for curved surfaces

Clear film: For a “no-label” look on transparent syringes

Paper labels: For dry environments or low-risk use

Sterile barrier options: For labeling outside primary sterile packaging

Adhesives:

Low-leach, medical-grade adhesives

Suitable for direct or indirect contact

Optional removable or tamper-evident designs

Printing Methods:

High-resolution digital or flexographic printing

Support for small text, barcodes, lot/expiry info

Variable data printing and blank areas for in-line printing

We help you select the right combination based on syringe size, storage conditions, and handling requirements.

What Customers Usually Ask

Will the label stay on such a small diameter?

Yes—we use thin, flexible materials and precise die-cutting to ensure smooth wraparound adhesion without lifting or bubbling.

Can I print barcodes and lot numbers on the label?

Absolutely. We support static and variable data printing, or can leave a blank section for thermal or laser printing at your facility.

Are the materials compatible with sterilization?

Yes. Upon request, we provide materials rated for EO, gamma, or autoclave sterilization. Let us know your process and we’ll recommend accordingly.

Do you offer tamper-evident features?

Yes. We can incorporate perforated edges, breakable seals, or other tamper-evident options based on your usage.

Can I request samples first?

Definitely. We provide physical samples for testing fit, material, and adhesion before you commit to production.

About Our Factory

With over 14 years in custom label manufacturing, we’ve supported the pharmaceutical, medical, and diagnostic sectors with precision-engineered labels that meet strict standards. As a direct-label printing factory, we control material sourcing, die-cutting, and quality checks in-house to ensure stable and reliable performance—especially in critical-use scenarios like syringe labeling.

We understand the importance of material compliance, labeling precision, and the risks of label failure in medical contexts—and we work closely with you to get it right.

Contact Us

Need reliable, customized syringe labels for clinical or pharma use?

Contact our team to discuss your exact requirements, label size, environment, and regulatory needs.

Email: zdlabel@hotmail.com

Samples available upon request.

We also provide dedicated solutions for skincare, haircare, and essential oil products—visit our Cosmetic & Personal Care Labels page.